Our Products

BUTTERFLY VALVE

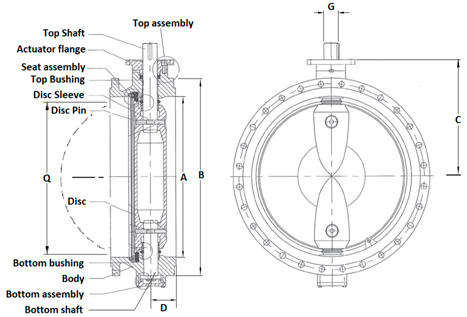

Large Size Double Flanged, Eccentric Design

Model K35: Large size Double Flanged Butterfly valve

Applications: Power plants, Water works, Municipal water treatment, Cooling systems, Industrial applications etc.

Suitable for on-off and control services

Range and Features :

| Type | Design | Pressure | Seat | Flange Suit To | Size(mm) |

| Double Flanged | Eccentric | PN6, PN10, PN16, PN20, PN25 | EPDM, BUNA-N, VITON | PN6, PN10, PN16, PN20, PN25,ANSI, JIS ANSI, BS, DIN, ISO, IS | 500 t0 2000 |

Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei Double flanged Eccentric Large Butterfly valves are designed to accommodate Flange drilling JIS, ANSI, DIN, BS. Also providing dead-end service capability with downstream piping removed. Each size valve flange has been designed to have the maximum outside diameter and maximum thickness of the nominated flange standards. K35 type valves provides the robust features to ensure reliable performance and long service life.

“A major advantage of Kansei product is an International compatibility.”

The valve face to face in accordance with EN 558, BS 5155 Short, ISO 5752 Table 4, EN-593 and AWWA C-504, AWWA C-207. Mounting cast flange designed in accordance to ISO 5211.

The Replaceable Seat design meets the requirements of seat replaceability on field without special tooling, dismantling and removing the valve from line. Also provide better shut-off and longer service life. The seat is of a molded construction and fits easily into the body which also reduce seating torque with disc edge contours. The Seat is adjustable to optimize the required shut-off tightness to comply the torque both for unidirectional and directional operation.

The Eccentric design provides energy efficient flow control. Stainless steel disc edge protects against corrosion and eliminates the possibility of restricted sealing. Upper and Lower shaft bearings prevent shaft deflection and provide optimum guidance to increase the valve life. High strength and Full diameter Shafts remain dry and provides positive disc control with a minimum flow restriction.

Sleeve bearings are self-lubricated which allows valve installation with the shaft vertical or horizontal. Thrust bearings are provided with the adjustment to ensure good axial positioning of the disc due to forces applied by seat and shaft seals to the disc. The secondary seal is provided to seal the bearing area from environment, and it will also act as a primary seal in account of failure of primary seal, Rubber lining is additional option for this product.

- Design standard as per EN 593, AWWA C-504, AWWA C-207 as standard, another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. 100% bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI / DI / NICI / NIDI / WCB / CF8 / CF8M / CF3M/ GR. 4A-5A / NAB etc. and Seat Material like EPDM / BUNA-N / VITON etc. Coating and Lining as per Customer requirement.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Gear / Pneumatic / Electric / Hydraulic Operation as per customer requirement.

TECHNICAL DATA

Size: 20” (500 mm) to 80” (2000 mm)

| Valve Size | A | B | C | D | G | Q | F to F |

| 500 | 500 | 670 | 505 | 70 | 50 to 60 | 460 | 229 |

| 600 | 600 | 780 | 565 | 85 | 50 to 60 | 555 | 267 |

| 700 | 700 | 895 | 623 | 86 | 50 to 70 | 658 | 292 |

| 750 | 750 | 965 | 598 | 105 | 60 to 80 | 703 | 318 |

| 800 | 800 | 1016 | 623 | 99 | 60 to 80 | 757 | 318 |

| 900 | 900 | 1116 | 673 | 97 | 60 to 90 | 859 | 330 |

| 1000 | 1000 | 1230 | 730 | 159 | 70 to 100 | 934 | 410 |

| 1100 | 1100 | 1340 | 798 | 197 | 80 to 120 | 1012 | 470 |

| 1200 | 1200 | 1455 | 848 | 185 | 80 to 120 | 1129 | 470 |

| 1300 | 1300 | 1575 | 918 | 212 | 90 to 140 | 1216 | 530 |

| 1400 | 1400 | 1675 | 968 | 219 | 90 to 140 | 1319 | 530 |

| 1500 | 1500 | 1785 | 1038 | 250 | 100 to 160 | 1405 | 600 |

| 1600 | 1600 | 1915 | 1088 | 243 | 100 to 160 | 1518 | 600 |

| 1800 | 1800 | 2115 | 1210 | 286 | 120 to 180 | 1711 | 670 |

| 2000 | 2000 | 2325 | 1333 | 350 | 140 to 200 | 1884 | 760 |

| Valve Size | Act. Flange | Appx. Weight in Kgs |

| 500 | F14/F16 | 215 |

| 600 | F14/F16 | 280 |

| 700 | F14/F16 | 390 |

| 750 | F25 | 465 |

| 800 | F25 | 525 |

| 900 | F25 | 645 |

| 1000 | F25/F30 | 885 |

| 1100 | F25/F30 | 1075 |

| 1200 | F30/F35 | 1300 |

| 1300 | F30/F35 | 1600 |

| 1400 | F30/F35 | 1930 |

| 1500 | F35/F40 | 2300 |

| 1600 | F35/F40 | 2690 |

| 1800 | F35/F40 | 3550 |

| 2000 | F40/F48 | 4595 |

Features and Benefits :

- Actuator/Gearbox mounting flange is standardized as per ISO 5211. Drilling & Tapping as per customer need.

- Valves are Double Flanged and Uni-directional.

- Pressure PN6, PN10, PN16, PN20, PN25. Temperature -30 to +120°C for EPDM, And Temperature -18 to +140°C for VITON.

- Operating with Gear, Pneumatic, Electric, Electro-Hydraulic etc.

- K35 Model offers low cost and excellent solution for Power generation, Municipal water treatment, Desalination plant and other Industrial applications.

- All dimensions are in mm and subject to change.

- Valve shape is for reference only.

- Q is the disc chordal dimension at valve face for disc clearance into pipe of equipment.

- Weight mentioned for bare shaft valve only and depends upon material used in valve.

- Dimensions are optimized to ensure efficient sealing performance.

- Wide options in Material, End connections, Face to Face dimensions.

- Coatings / Rubber lining options also available as per customer requirement.

General Notes :

-

- Customization and Automation as per customer requirements.

- Certificate of compliance to EN10204 Type 3.1 as standard.

- Safety stock as per customer requirements.

- 100% factory tested and inspected valves as per standard.

- Other trims also available as per customer requirements.

- Support to customers for other product requirements from sources.

- Consult to Factory for Torque and Other Details.