Our Products

BUTTERFLY VALVE

PFA/PTFE Lined, Centric Bi-directional

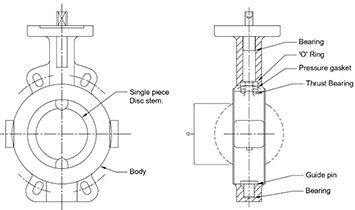

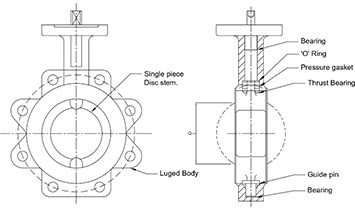

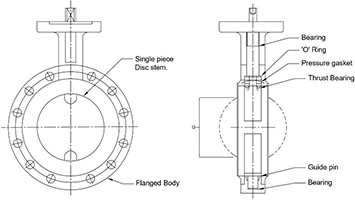

Model K51-W: Wafer type , Model K52-L: Lug type &

Model K53-F: Flange type

Applications : This type of valves are used for multitude and corrosive application, Hazardous and pure liquid, gas, & vapors, free flowing. e.g.: Pharma, foundries and mining, chemicals and petrochemicals, pulp and paper industries, under vessels, & specially used where constant torque and no maintenance is required .

Suitable for on-off and control services

Range and Features :

| Type | Design | Pressure | Seat | Flange Suit To | 2" to 16" |

| Wafer | Centric Bi-directional | PN10, PN16 | PTFE, PFA, PFA CONDUCTIVE, TFM, TFM CONDUCTIVE | ANSI 150# | |

| Lug | Centric Bi-directional | PN10, PN16 | PTFE, PFA, PFA CONDUCTIVE, TFM, TFM CONDUCTIVE | ANSI 150# | |

| Flange | Centric Bi-directional | PN10, PN16 | PTFE, PFA, PFA CONDUCTIVE, TFM, TFM CONDUCTIVE | ANSI 150# |

Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei PFA/PTFE Lined Centric Bi-directional Butterfly valves are designed to ensure a tight fit around the disc for bubble tight shut off in both direction and provide a constant torque with no maintenance.

“A major advantage of Kansei product is an International compatibility.”

The Exceptional Design of one-piece thin disc stem lined with 3mm molded PFA providing high Kv value. The liner and disc are the only two valve parts in contact with the medium.

Kansei improved design of disc leading to less deflection at higher pressure and tighter in line seal and for stem sealing system.

Primary shaft sealing by preloaded contact between disc and liner hub and the secondary shaft seal by oversizing the shaft diameter in relation to the shaft hole in the liner. The liner and disc are molded and machined to close tolerances to provide low torque, less stress and deformation using opening and closing.

PTFE atmospheric seat protects internal components from atmospheric corrosion and provides locating ring for actuator mounting. Fully encapsulated bottom shaft eliminates potential leak path at bottom of valve and eliminates the necessity for further sealing elements

- Design standard as per EN 593 or API 609 as standard, another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. 100% bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI/ DI/ WCB/ CF8M/ CF3M/ GR. 4A-5A/ etc. and Seat Material PTFE.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Lever / Gear / Pneumatic / Electric Operation as per customer requirement.

Valve Operations :

TECHNICAL DATA

Model K51 W - Size: 2” (50 mm) to 12” (300 mm)

Model K52 L - Size: 2” (50 mm) to 12” (300 mm)

Model K53 F - Size: 14” (350 mm) to 16” (400 mm)

Features and Benefits :

- Actuator/Gearbox mounting flange is standardizedas per ISO 5211.

- Lugged body has drilled and tapped (matric or imperial) options as per ANSI, PN10 & PN16

- Seat Provides maximum abrasion, wear resistance and a high impact resistance.

- Valve is suitable to sandwich between ASME B16.5 and 150# flanges.

- Operating with Lever, Gear, Pneumatic, Electric etc.

- Valve shape is for reference only.

- Q is the disc chordal dimension at valve face for disc clearance into pipe of equipment.

- Actuator mounting flange is in accordance to ISO 5211.

General Notes :

-

- Customization and Automation as per customer requirements.

- Certificate of compliance to EN10204 Type 3.1 as standard.

- Safety stock as per customer requirements.

- 100% factory tested and inspected valves as per standard.

- Other trims also available as per customer requirements.

- Support to customers for other Products requirements from sources.

- Consult to Factory for Torque and Other Details.