Our Products

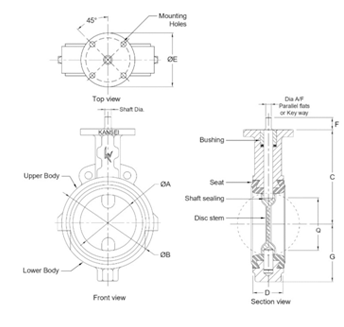

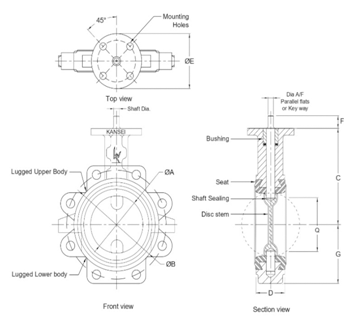

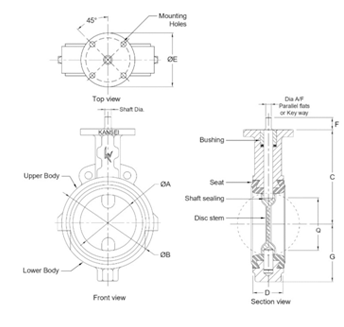

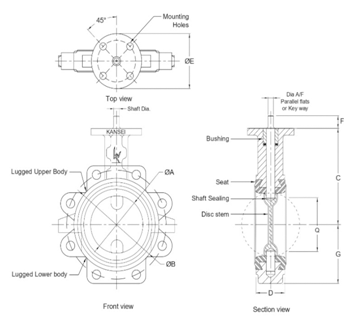

EPDM, PTFE Seated Centric Bi-directional Butterfly valve Wafer and Lug

Model K61 W - Size: 2” (50 mm) to 20” (500 mm) :

Model K62 L - Size: 2” (50 mm) to 20” (500 mm) :

Dimensions - Wafer & Lugged

| Valve Size |

Shaft Dia |

A |

B |

C |

D |

E |

F |

G |

Q |

| 50 |

14.28 |

65 |

117 |

151 |

44 |

102 |

32 |

76 |

48 |

| 80 |

14.28 |

78 |

130 |

160 |

44 |

102 |

32 |

88 |

65 |

| 100 |

15.9 |

103 |

162 |

177 |

51 |

102 |

32 |

102 |

90 |

| 125 |

19.05 |

129 |

187 |

190 |

54 |

120 |

32 |

119 |

118 |

| 150 |

19.05 |

148 |

216 |

204 |

54 |

120 |

32 |

133 |

138 |

| 200 |

22.25 |

198 |

271 |

242 |

64 |

152 |

32 |

170 |

188 |

| 250 |

28.58 |

249 |

330 |

271 |

64 |

152 |

51 |

210 |

241 |

| 300 |

28.58 |

300 |

375 |

313 |

76 |

152 |

51 |

238 |

191 |

| 350 |

28.58 |

339 |

429 |

304 |

76 |

152 |

76 |

248 |

331 |

| 400 |

41.28 |

390 |

489 |

337 |

102 |

152 |

69 |

279 |

377 |

| 450 |

47.64 |

441 |

546 |

369 |

108 |

203 |

108 |

314 |

428 |

| 500 |

54 |

491 |

603 |

402 |

127 |

203 |

108 |

449 |

475 |

Mounting Flange

| Valve Size |

PCD |

NO. OF HOLES |

HOLE DIA |

| 50 |

83 |

4 |

11 |

| 80 |

83 |

4 |

11 |

| 100 |

83 |

4 |

11 |

| 125 |

83 |

4 |

11 |

| 150 |

83 |

4 |

11 |

| 200 |

127 |

4 |

14 |

| 250 |

127 |

4 |

14 |

| 300 |

127 |

4 |

14 |

| 350 |

127 |

4 |

14 |

| 400 |

127 |

4 |

14 |

| 450 |

165 |

4 |

21 |

| 500 |

165 |

4 |

21 |

Appx. Weight in Kgs

| Valve Size |

Wafer |

Lugged |

| 50 |

2.8 |

3.1 |

| 65 |

3.5 |

4.5 |

| 80 |

4.3 |

4.6 |

| 100 |

5.2 |

7.5 |

| 125 |

7 |

10.1 |

| 150 |

8 |

11 |

| 200 |

14.2 |

19.1 |

| 250 |

20 |

29.2 |

| 300 |

35.3 |

49.1 |

| 350 |

48 |

65 |

| 400 |

81.9 |

107.5 |

| 450 |

101.1 |

118.2 |

| 500 |

142.5 |

167.0 |

Features and Benefits :

- All dimensions are in mm and subject to change.

- Valve shape is for reference only.

- Q is the disc chordal dimension at valve face for disc clearance into pipe of equipment.

- Weight mentioned for bare shaft valve only and depends upon material used in valve.

- Actuator / Gearbox mounting flange is standardized as per ISO 5211.

- Lugged body has drilled and tapped (metric or imperial) options as per ANSI, PN10 and PN16.

- Operating with Lever, Gear, Pneumatic, Electric etc.

- Automation as per customer requirement.

- Consult to factory for Torque and other details.

- Customization and trims as per customer requirements.

General Notes :

- Customizaticn and automation as per customer requirements.

- Certificate of compliance to EN10204 Type 3.1 as standard.

- Safety stock as per customer requirements.

- 100% factory tested and inspected valves as per standard.

- Other trims also available as per customer requirements.

- Support to customes for other project requirements from sources.

×

![]()

×

![]()

×

![]()